GBB Concept

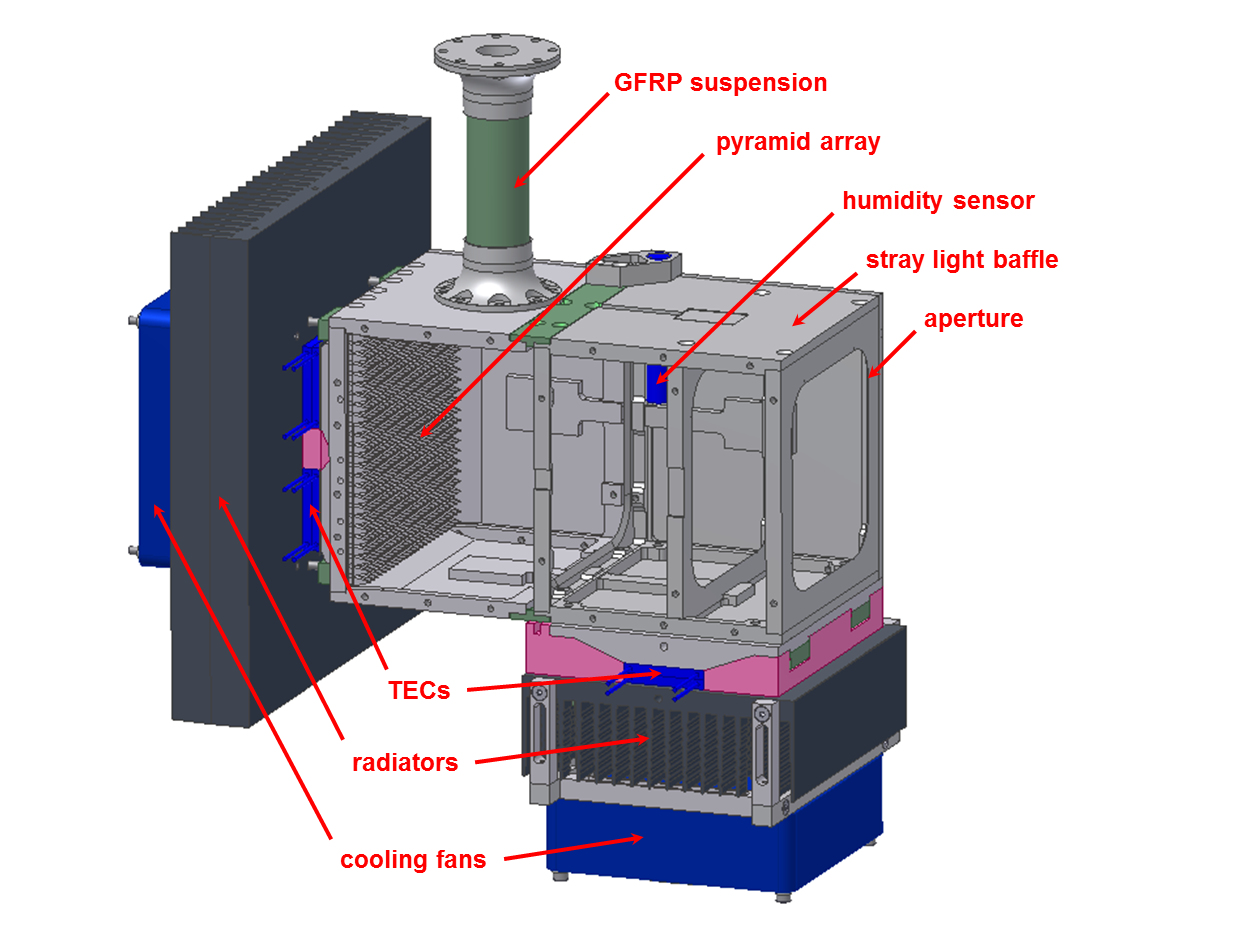

The GLORIA in-flight calibration system (see Fig. 1) consists of two identical high-precision blackbody radiation sources, which are independently controlled at two different temperatures and emit radiation in the range of the atmospheric infrared radiance emissions. In order to operate one blackbody at 10 K below and the other at 30 K above ambient temperature, Thermo-Electric Coolers (TECs) are used offering the advantage of avoiding cryogens and mechanical coolers. An additional benefit of TECs is the dual utilization for cooling and heating by just switching the direction of the electrical current.

|

|

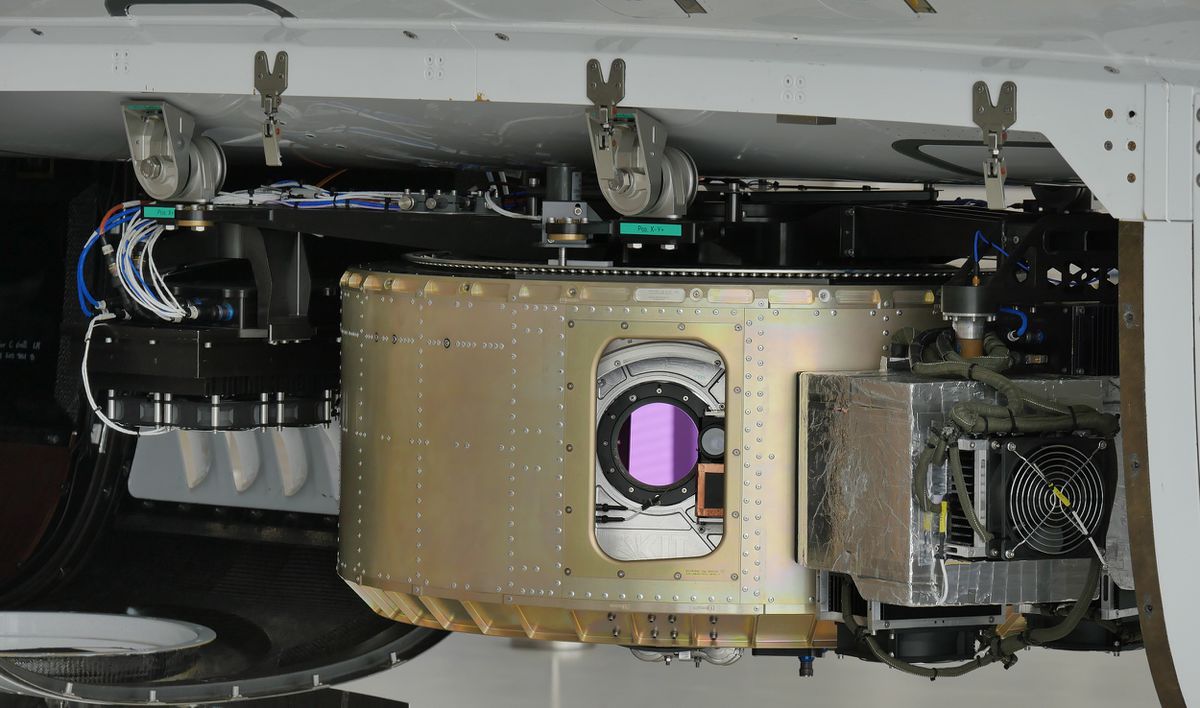

| a) structural design | b) GBBs mounted on GLORIA |

The GBBs have been comprehensively characterized spatially (full aperture) and spectrally (7 µm to 13 µm). The radiation properties in terms of radiation temperature are traceable to the international temperature scale (ITS-90) at the national metrology institute of Germany (PTB).

| Optical surface | 126 mm x 126 mm |

| GBB temperature | = ambient temperature - 10 K / +30 K |

| Temperature uncertainty | < 0.1 K |

| Emissivity | < 0.997 |

| Spatial temperature inhomogeneity | < 0.150 K |

| Long-term temperature stability | < 0.025 K/min |

GBB Design

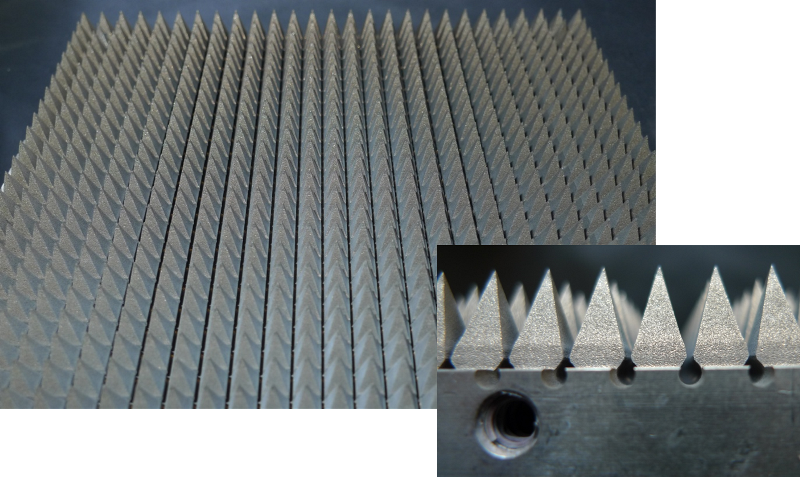

The optical surface of a GBB (see Fig. 2) consists of an array with 25 x 25 pyramids (about 8mm high) made of aluminum. The pyramids as well as the inner walls are varnished with NEXTEL-Velvet Coating 811-21.

|

|

| a) Array of 625 individual pyramids |

b) varnished with NEXTEL-Velvet Coating |

The optical surface of a GBB is temperature-controlled by a system consisting of an assembly of four two-stage Thermo-Electric Coolers (TECs). The aluminum casing around the optical surface is partly thermally decoupled. The front part serves as a stray light baffle which is also temperature-controlled by TECs (see Fig. 1a). The stray light baffle is operated at a slightly lower temperature in order to act as a water vapor trap to inhibit condensation on the black optical surface.

Temperature is measured at 10 positions distributed over the optical surface using PRTs (platinum resistance thermometers). Four PRTs are placed directly under the TECs. These are used for the temperature control, the other 6 sensors are used for monitoring.

The GBBs are suspended by GFRP (Glass-Fibre-Reinforced-Plastic) tubes for thermal decoupling. In order to reduce the adverse influence of the thermal environment, the GBBs are covered with a 50 mm-insulation made of extruded polystyrene foam (XPS) sheets. The outermost layer of the cover is composed of aluminum foils for EMC (Electro-Magnetic Compatibility) reasons. The overall weight of one GBB is 9.5 kg.